NEW QBL Chiller at FABTECH 2022

Chase Cooling Systems Announces Display of NEW QBL Chiller at FABTECH 2022

Chase Cooling Systems announces its participation in Fabtech 2022 in Atlanta, GA November 8-10, 2022. FABTECH is the North America’s largest metal forming, fabricating, welding, and finishing event.

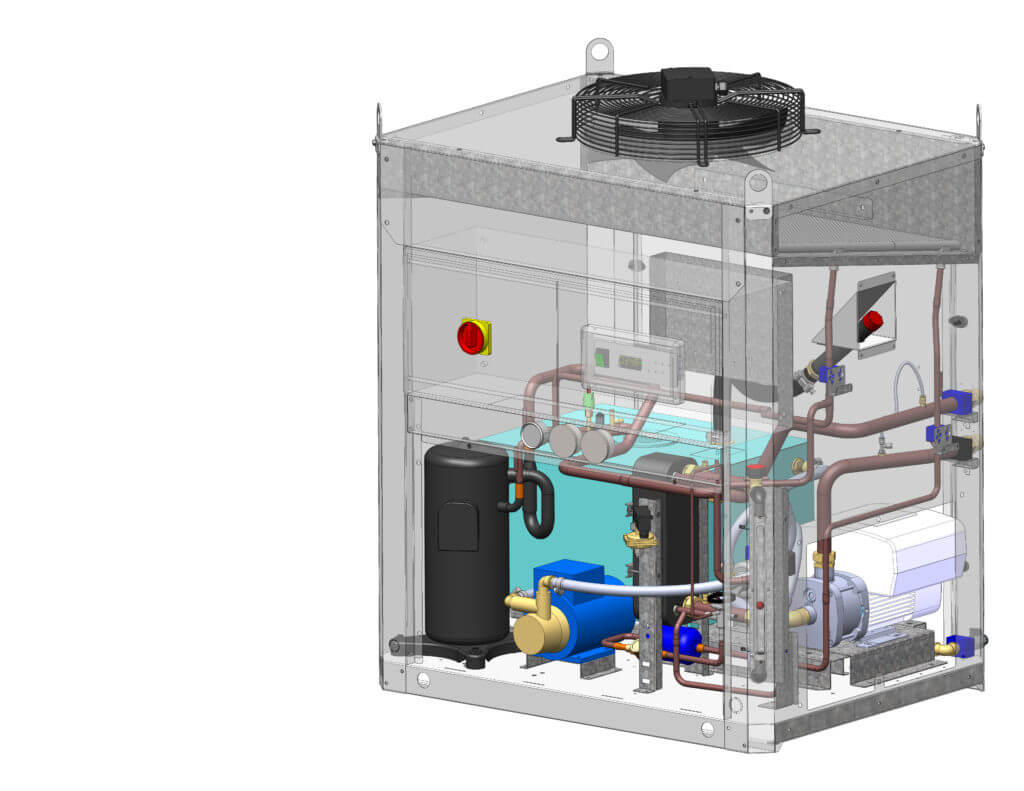

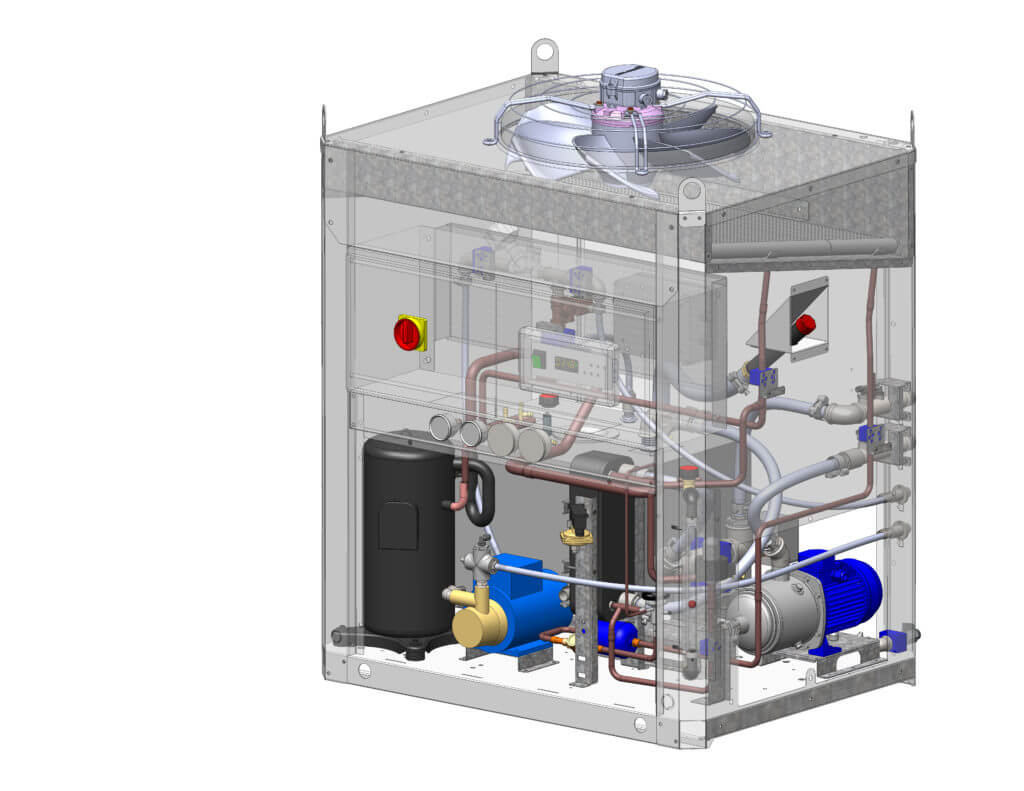

This year Chase Cooling Systems will display a chiller unit from the QBL Series. The chiller and Chase Cooling Systems representatives will be in Booth B7948. The display unit, the QBL017-R, is an expansion of the QBL Series. The QBL017-R caters itself to the cooling needs of the laser industry. It provides just under 6 tons of cooling and has pump flows of 12.9 and 0.5 gallons per minute.

The entire QBL Series ranges from 2 tons to 17.5 tons of cooling capacity. Every unit in the series comes equipped with two independent cooling circuits; each has its own pump. One circuit can cool the laser optics and one can cool the laser source. The series’ compact footprint allows users to get more out of a single unit. Each cooling circuit is fully independent of the other and allows users to set each to different temperatures.

“We are quite excited to introduce this new laser specific chiller to the expanding laser marketplace,” says Chip Miller, sales manager at Chase Cooling Systems. “Chase Cooling Systems’ range of sizes and history of reliability will make this chiller a great option for so many OEMs and end users.”

More information about FABTECH2022 can be found at their website: www.fabtechexpo.com

Click here to register to attend FABTECH 2022!

Customer Highlight: Tire Valve Manufacturer

Tire Valve Manufacturer Uses Chase Chillers to Power Cooling System

At Chase Cooling Systems, we value the individuality of each of our customers. They have different demands with varying conditions. All of it matters to us when we are designing the best cooling system. Recently, we assisted a leading tire valve manufacturer in establishing consistent cooling in their new facility.

During the manufacturing process, the product may be subject to very high temperatures, mostly centered in the brazing furnaces. The brazing furnaces melt and mold the raw materials as needed. The high heat is crucial to create the best final product. However, equally important is the system’s ability to rid itself of this heat.

That’s why the cooling system is so critical! To provide cooling to brazing furnaces, the facility chose to use a unit from our CWE series. The chiller provides chilled water at 55°F temperature to the cooling tunnels immediately following the three brazing furnaces. These cooling tunnels have a combined heat load of 150,000 Btu/h. Fortunately, the CWE068 under these conditions has a cooling capacity of 180,000 Btu/h, easily meeting the current heat load and providing room for increased demand. A properly sized system is crucial to system success. Though it may be tempting to vastly oversize the system, that will only cause problems in the future. Proper system sizing is key to the long-term success of the cooling system.

To best accommodate varying flow rates, the CWE Series unit for this project includes a VFD process pump. The flow rate for the application can vary from as much as 10 gallons per minute to as little as 2, a range of 5:1! The VFD pump allows for a constant system pressure, regardless of the flow rate required, preventing over-pressurization of the tunnel cooling circuits. Variable speed control is not limited to the pump. In fact, the chiller condenser is equipped with variable speed fans that enable efficient heat removal while maintaining proper refrigerant pressures throughout a wide range of operating conditions.

Other notable modifications for this system include the ductable condenser fans. This feature exhausts heat outside of the facility or, if desired, recaptures it for winter temperature control. We like to build in energy saving potential whenever we can!

We at Chase Cooling Systems were so excited to be able to work on this excellent application and are proud to support the successful cooling of this process.

Springtime Chiller Maintenance

Springtime is here once again and it is the perfect reminder to check on your industrial chiller. Sure, it may not have been working as hard during the cold months of winter, but as summer approaches, it will be needed even more. A well running chiller is critical for your process, and you don’t want any interruptions in that service. Use these tips to help keep your chiller in reliable working condition, especially during spring maintenance.

- Conduct a Comprehensive Inspection

Before powering your chiller up after any sort of shutdown, you want to perform a thorough visual inspection. Are there any loose connections? Is there an obvious issue with the control panel or the chiller cabinet? Any decay or build-up of debris? Make sure to really look over every element you can. If you can spot something before startup, you may be able to save yourself from causing a more extensive repair down the line.

- Test All Equipment Controls

You always want to make sure the sensor readings on your machine are accurate. These readings help you to understand your chiller input and output. However, if the readings are wrong, your whole process could be in danger! Spring maintenance is a perfect time to calibrate the sensors and controls. Check electrical connections throughout the control cabinet and tighten or repair any that are loose. Ensure all motor overloads are set according to each motor’s nameplate and/or according to the unit’s wiring diagram.

- Clean the Condenser Coils (Air-Cooled Chillers)

An early indication that your unit needs to have its condenser coils cleaned is repeated or intermittent alarms for high refrigerant pressure. The accumulation of dust and debris prevents efficient heat transfer across the condenser, resulting in higher-than-normal refrigerant pressures. You may also see increased power consumption, as dirty condenser increases the fan power requirement; elevated refrigerant pressure also places unnecessary load on the refrigerant compressor(s) and raises their power input. When your chiller’s condenser is dirty, it can’t run as reliably or as efficiently as it needs to. By pre-emptively and consistently cleaning your unit, you can keep your chiller operating like new.

- Maintain Water-Cooled Condensers

Like an air-cooled condenser, water-cooled units must be kept clean to ensure high efficiency and proper flow of the cooling medium. The heat transfer surfaces (usually plates or tubes) have tortuous passages and can become coated with slime, sludge, and scale, preventing efficient heat transfer. Water quality largely determines the rate of this buildup. Be sure to clean any strainers and replace filter elements as they become restricted. Always have a qualified expert check the water chemistry to ensure it is up to standards, too. If a water control valve regulates the cooling water, check that it is operating properly and not wasting water. Regularly performing these maintenance tasks helps to maintain efficient chiller operation and prevent unexpected shutdowns.

- Perform any repairs

Waiting to complete repairs will only exasperate any problems. If you or a trained technician have spotted any issues with your chiller system, it is imperative that you address them before putting the chiller back into use. Choosing to forgo important repairs will almost certainly cause more failures in the future (and probably at an inopportune moment!). It is much better to fix smaller problems in a scheduled manner, instead of waiting for a bigger shutdown to arise.

- Create a Maintenance Schedule

Now that you’ve reviewed the most pressing concerns for your industrial chiller, you should set up a maintenance schedule for smaller tasks. Ideally, smaller check-ups should occur throughout the year to ensure proper care for your unit. If you need assistance putting together a check-list, you can always reach out to the manufacturer. You can’t just create the schedule though; you HAVE to follow it. Write down particular times for maintenance to be done and actually go through with the steps.

Whether you perform some spring maintenance or spread it out throughout the year, quality preventative maintenance is crucial to a well operating industrial chiller. Take the time this spring to go over your unit. You'll hopefully find you have a strong, more efficient chiller as a result.

Don't forget to read our previous blogs about Chiller Preventative Maintenance!

Incorporating Cooling Power into the Food & Beverage Industry

Chillers in the Food & Beverage Industry

Most food & beverage companies need at least one cooling system in their process. Typically, health & safety guidelines mandate that a product must be kept at a particular temperature. To best integrate cooling into a system, a full understanding of the needs of a product and its components must be obtained.

Different steps along the manufacturing process may have different acceptable temperature ranges. Certain materials may require a lower temperature to support peak freshness; some steps, such as blast freezing, may change the makeup of the product and dictate a new temperature. Food safety is important for any food & beverage company. Temperature often plays a vital role in keeping bacteria growth controlled. A comprehensive understanding of all the various temperature requirements across a system will help to create the most exact cooling system.

After an initial temperature analysis, a cooling engineer can help to decide the best way to add cooling to the system. One of the most common cooling integrations in the food & beverage industry is directly cooling the conveyor belt that moves material. By using thermal contact to conduct heat, a cooled conveyor belt may be able to keep ingredients at the right temperature as they move.

An industrial chiller achieves this cooling effect by using a dual circuit set-up. One circuit, known often as the cooling circuit, pipes a cooling fluid to the process area. After it absorbs heat from the process (indirectly from the warm food through the conveyor belt), the fluid moves back to the chiller. There the warmed process fluid will travel through the evaporator. The second circuit, the refrigeration circuit, will meet the process fluid and absorb its heat here. Once finishing in the evaporator, the process fluid is cooled enough to return to the process and continue its cooling work. Meanwhile, the now vaporized refrigerant will travel to the condenser to be cooled and made ready to meet with the process fluid again.

To set up a proper cooling system for the specific food & beverage process, a cooling engineer will need to know the temperature cooling differential as well as the number and frequency of different cooling areas. Multiple industrial chillers could be used or it may make more sense to build a larger central cooling system. Knowing the desired water flow and pressure will also be necessary to properly size a solution. An expert cooling engineers will be best able to help decide what possibility makes the most sense.

Integrating cooling systems into a food & beverage system may seem overwhelming at first. There is a lot to know and understand about refrigeration systems. But with help from cooling experts like those at Chase Cooling Systems, the result is sure to be a reliable system that will produce the best products.

New Laser Series Chillers to Debut at FABTECH 2019

New Laser Series Chillers to Debut at FABTECH 2019

Chase Cooling Systems will exhibit at FABTECH 2019. This annual tradeshow focuses on the metal forming, fabricating, welding, and finishing audience. It seeks to be a “one-stop shop” where attendees can meet with suppliers, see the latest industry products, and find productivity-increasing tools. The convention will occur this year in McCormick Place, Chicago, Illinois from November 11-14th.

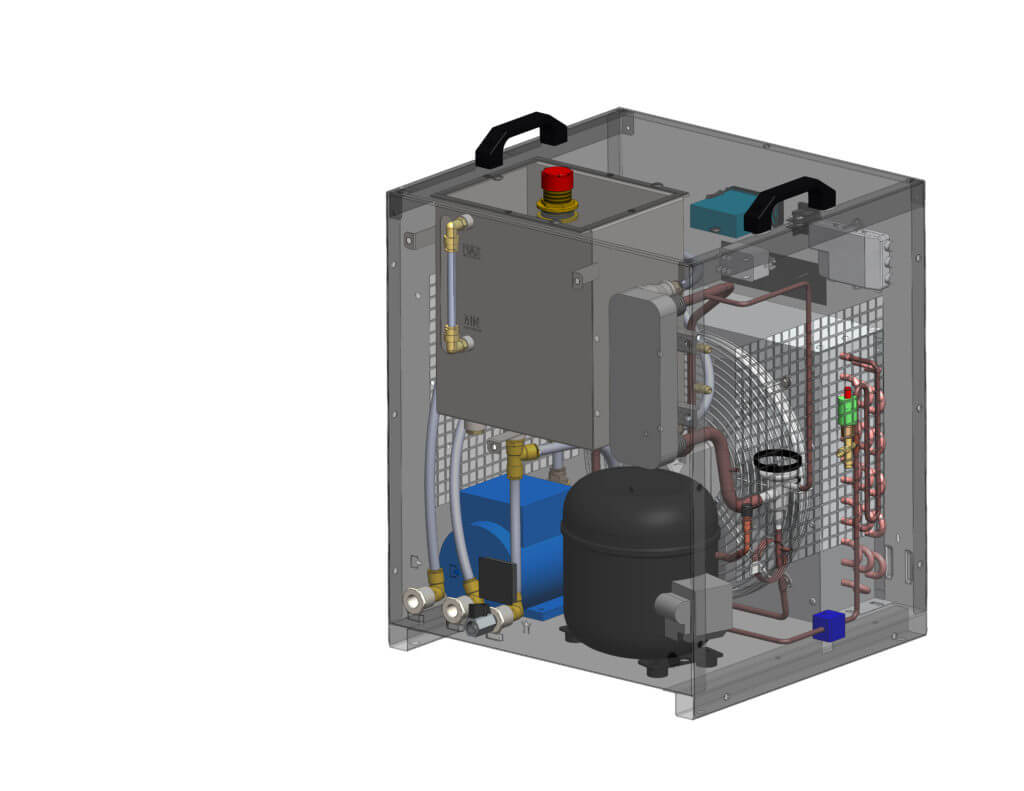

This year at the show, Chase Cooling Systems will feature a unit from its newest chiller series, the Laser Series. Chillers in this series include features specifically crafted to be useful for industrial laser applications.

Standard features for these chillers vary by model and include a non-ferrous water circuit, VFD pump, and hot gas bypass valve. These design elements position the machine to provide constant water temperature without the risk of corrosion. The hot gas bypass valve allows for tight temperature control of ±0.1°C (±0.18°F), which can be very important for cooling laser applications.

Units in the series exist in three distinct configurations. Each arrangement focuses its cooling on a different element: the laser source, the optics, or both. Renderings of the three divisions can be seen above.

The unit on display at FABTECH 2019 will be model QBE014 LASER 2 LINES. This chiller contains two water circuits in a single machine. Each circuit can maintain a different temperature and separately cools both the optics and the laser source at the same time. Users can individually adjust the temperature for each circuit to ensure optimum operation of the laser optics and source. An electric heater also comes standard to maintain a set minimum temperature and avoid the problems associated with cold start-ups.

Units in the new series range from 0.5 to 7 tons of cooling capacity. Available sizes depend on required features and capabilities.

In addition to the new Laser Series unit, Chase Cooling Systems will display other chillers applicable to the metal industry in Booth A3105. There will be both a ACW dry cooler and a small QBS fluid chiller. A QBE unit featuring a NEW stainless-steel housing will also be present.

Visitors are encouraged to stop by Booth A3105 during the show to check out these units in person. Cooling engineers will also be available throughout the week to discuss specific cooling applications and answer any questions.

Free tickets are available to FABTECH 2019 courtesy of Chase Cooling Systems. Simply use the promo code: 16029733 or for quick registration, sign up here.

Find more information about FABTECH 2019 and a complete list of vendors on their website, www.fabtechexpo.com

Refrigeration & Winemaking

Where is cooling used when making wine?

The art of winemaking goes back centuries. Over the years, technology has improved enabling greater experimentation and refinement in the winemaking process. However, a well-maintained temperature system remains at the core of producing a great tasting final product. Whether looking to break into the wine industry or seeking to update existing wine systems, understanding the role of refrigeration in the process helps users to better manage their set-ups.

Temperature control impacts several distinct steps in the winemaking process:

Must Cooling

Must is the freshly crushed grapes. This mixture contains skins, seeds, and stems of the fruit. Creating the must is the first step in the winemaking process. In the commonly evoked images of medieval people stomping in large barrels the juicy grape mush is the must. Though only the beginning, the length and temperature at which the must stays in this stage influences the final flavors of the wine. The must should be kept around 40° F in order to limit phenolic oxidation and premature fermentation. Sometimes vintners will employ cryomaceration, which involves a deep cooling almost to a freezing of the must. Cryomaceration extracts greater flavor compounds from the grape skins than other must cooling options.

Juice Clarification

After further processing of the must, only the juice remains. Once again cooling becomes a crucial element. A good quality wine should be “clear” with no visible particles in the liquid. In order to avoid the dull & cloudy look, the pre-fermented juice must undergo clarification. Depending on the variety of grape and the specifics of the wine, different methods can be used. However, the most common method across varieties involves using a cooling jacket around the wine barrels. The exact temperature will vary depending on the type of wine, but should be somewhere between 50-58° F. At the lower temperature, much of the acidic components, which contribute to cloudiness, break down.

Fermentation

This step is generally the longest in the process. It involves the careful management of added yeast, which break down the sugars present in the juice. As the yeast consume the sugar, the liquid ferments and receives its alcoholic content. Of course, this process is very particular, as yeast are feisty fellows. Many factors contribute to the rate of fermentation and the final flavor, but temperature remains the key determinant. Temperature must be properly set and maintained in order to produce flavorful wine. Fermentation is an exothermic reaction, meaning it releases heat. The cooling system must be able to remove this naturally created heat before the mixture becomes too hot. The fermentation process could stop if temperatures become too high.

Generally, industrial chillers will cool the fermentation tanks. The chiller moves cooling fluid through the tank to absorb and remove the heat. The result is a lowered temperature in the tank. Chillers can also typically provide valuable process information such as temperature readings. Depending on the model of the chiller, users may even be able to adjust temperature settings to correspond with the needs of the particular wine.

Certain fermentation processes even require the addition of heat in order to produce the desire final product. The heat prevents malolactic fermentation and protects the wine from developing a bad taste. Chase Cooling Systems offers a heating pump option on our CWE/HWE series. With the proper set-up, one unit can be used to either heat or cool the process.

Cold Stabilization

Once the juice has fermented, it has to undergo cold stabilization. A common biproduct of the fermentation process is potassium bitartrate, which can crystalize and form precipitate in the wine. This sediment can create an unpleasant appearance, and it is best if it is removed prior to bottling. By rapidly lowering the temperature of the fermented juice, much of the tartaric acid will precipitate out. The liquid can then be filtered and bottled. The bottled liquid should form significantly less sediment after the cold stabilization process.

Wine Storage

Once the wine is bottled, it must be kept at the proper temperature for storage. Temperature is particularly important if the wine will not be served immediately. Finding the “perfect” temperature depends on the specifics of the wine but generally is in the 62-68° F for reds and 49-55° F range for whites. Maintaining these temperatures helps to limit the rate of oxidation and the volatility of the aroma compounds. Essentially, the cooler temperatures protect and preserves the wine, making it enjoyable for a longer time and better ready for market. In ambient temperatures above 70° F a wine can begin to age and lose its flavors.

Space Cooling

Outside of the actual winemaking process lays another need for refrigeration. The general space where the process occurs and where wine barrels are kept should be temperature controlled. As demonstrated above, the winemaking process is very particular and the smallest changes in temperature can have large effects on the final product. Hence, why caves often served as wine cellars in the early days. The most common method to achieve this periphery cooling is by utilizing some type of HVAC system.

In summary…

Refrigeration plays a role in almost every step of the winemaking process. Though different refrigeration methods may be utilized throughout, the impacts are very real. Understanding how temperature effects this delicate process is crucial to producing successful final product.

To discuss the specific needs of your winemaking system, be sure to call a cooling engineer at Chase Cooling Systems. Or send an email to sales@chasechillers.com. We would love to help work you through that final hurdle to producing consistent delicious product.

A Brief History of Refrigeration

Happy World Refrigeration Day!

Today is World Refrigeration Day!

The first of what will hopefully be an annual celebration highlighting the important contributions of refrigeration in our everyday lives. In honor of this very special day, Chase Cooling Systems wanted to contribute a brief history of refrigeration and its growth into such an important industry.

Refrigeration in the broadest sense of the world refers to any process that lowers and maintains a temperature below the temperature of the surrounding ambient. The concept of refrigeration and cooling objects has been around a long time. Evidence of ice houses go back to Mesopotamia in 1780 BC and evaporative cooling Yakhchals have existed since 400 BC in Persian deserts. Needless to say, humans have long recognized the importance and the power of refrigeration.

Early Mechanical Refrigeration</font color>

The first instance of using mechanical refrigeration, however, was not until 1755. Scottish professor William Cullen drafted a machine that used a pump to create a vacuum in a container of diethyl ether. The vacuum lowered the boiling point of the ether and allowed the ether to absorb more heat from the surrounding air when boiled. Though hailed as a useful advancement, no practical application resulted.

Vapor-Compression Cycle</font color>

Fifty years later the American Oliver Evans expanded on this principle with his invention of the closed vapor-compression cycle. He used Cullen's understanding of a lowered boiling point in a vacuum and demonstrated how the vapor could be used to cool. However a working model was not created until 1835 by Jacob Perkins. Another 7 years were needed before John Gorrie created a commercially successful one! Gorrie was able to use the vapor-compression cycle to cool hot air in rooms. Unfortunately, his unit required too much ice to provide lasting, practical cooling.

Finally, in 1851 British journalist James Harrison used the technology to artificially create ice. By using ether, alcohol, or ammonia as opposed to simple air, Harrison's invention allowed both the reuse of cooling agent and for temperatures to be brought well below the freezing point of water. Harrison used a compressor to force the refrigeration gas through a condenser where it cooled and liquefied. The cooled gas than circulated through coils and vaporized, cooling the surrounding process. His refrigeration cycle essentially matches the existing cycle today. The first uses for these machines were in breweries and meat packing houses. Both industries still rely heavily on refrigeration and chillers for their processes today. With regular refrigeration, breweries could make consistent product year-round. Learn more about process cooling in the brewery industry.

Artificial Cooling Expands</font color>

Other industries soon saw the benefits of artificial cooling. In metalworking, tools could be tempered. With less moisture in the air, iron production could increase. Even textile mills found a use for refrigeration during the bleaching and dyeing processes. Floral seasons were extended and human bodies could be better preserved for study. Refrigeration found a use in almost all industries from oil refineries to paper manufacturers to fur warehouses. Many of these processes, though touched by innovation, continue to rely heavily on process cooling.

In the early 20th century, the mechanical refrigerator underwent several changes & improvements. Eventually, the Frigidaire Company purchased the compressor-variant refrigerant in 1918. With a solid design & large company capital, the mass production of refrigerators for the home began. Other companies soon joined in and by the middle of the 20th century, the icebox was virtually gone from the American home. In its place stood the reliable home refrigerator.

Refrigeration Today</font color>

Though now a staple of the both home & industrial life, the refrigeration & cooling industry continues to see advancements. Particular areas of concerns revolve around the cooling agents. Ammonia was the original coolant, but its high toxicity, especially in the case of leaks, was problematic. Today synthetic refrigerants such as R410A and R134 are most common. Though recent environmental concerns have lead to the need for further innovation and answers.

Refrigeration exists in many forms across our modern lives. From the manufacture of daily products to the preservation of food to the development of lifesaving processes & medicines, refrigeration is pivotal to our current lifestyles. Today on this World Refrigeration Day, take a moment to appreciate the role of refrigeration in your life.

For more events and information about World Refrigeration Day, check out the International Institute of Refrigeration’s Facebook Event page. Or follow the conversation on Twitter using the hashtag #wrefd19. Let us know how you are choosing to celebrate the history or refrigeration.

Glycol FAQ

Everything you need to know about Glycol

Glycol is a very important element in any cooling system. Despite its ubiquity and its importance, most customers don’t fully understand all that it does. In an effort to clear up some of the confusion about glycol, here are our answers to the most commonly asked questions.

What is Glycol?

Glycol is a water-miscible organic compound in the alcohol family. It is commonly used for cooling in industrial and mechanical applications. Glycol is sometimes called antifreeze or a coolant. Though it acts similarly to a refrigerant, and someone may refer to glycol as a refrigerant, this statement is incorrect. Glycol cools solely through heat transfer in an exchanger; whereas, refrigerant uses an evaporation-condensation cycle to remove heat.

What does glycol do in a processing cooling system?

The most important role glycol plays in a process cooling system is to adjust the temperature range of the system. Without any glycol in the system, the water will freeze at the normal 32°F (0°C). In this case, the system ambient temperature can never go below this temperature. However, many systems need temperature flexibility as pipes travel outside and into unheated areas. Adding glycol to the water lowers the freezing point. The percent of glycol determines what the new freezing point will be.

A lower freezing point means process fluid can be kept at colder temperatures. A greater difference between medium temperatures allows for a faster heat transfer process. Heat always travels in the direction of higher temperature to lower temperature. When a coolant with a colder temperature is used, more of the energy can be transferred from the other fluid or process to the coolant.

What are the benefits of using glycol in my system?

Glycol often contains corrosion inhibitors which can help to prolong the life of components. Its main function is to enable a cooling system to operate at temperatures below the freezing point of water. Certain systems may require this lowered cooling for optimum performance.

What percentage of glycol does my system require?

Deciding on the perfect glycol-water mixture is critical to your chiller's operation. You will need to consider factors such as ambient temperature, desired lowered temperature, and heat transfer rate. The best way to determine a percentage for your system is to talk to a Chase Cooling Systems Expert. As there can be adverse effects on the cooling system when using glycol, the glycol concentration should be limited only to what is required for freeze protection.

Are there different types of glycol?

Yes. There are two types of glycol commonly used for process chillers: Propylene and Ethylene Glycol. These products vary on metrics such as performance, environmental factors, and general safety. The specific needs of your process will determine which glycol type is best for your system.

Is glycol safe to use around food and beverage products?

In general, propylene glycol is considered food grade and can be used in food and beverage operations. Most brewery applications use this type of glycol. Additional certifications such as United States Pharmacopeia (USP) stamp can be sought to ensure that any glycol in the mixture indeed is safe for consumers.

Where can I purchase Glycol?

Glycol can be purchased from reputable vendors, including Chase Cooling Systems. When purchasing glycol, know the concentration you need and the concentration you are purchasing. Glycol comes in stock concentrates as well as in set blends. It can be ordered in 55 gal drums, 5 gal pails, or bulk 275 gal totes. Always make sure you are purchasing the appropriate grade glycol. Automotive anti-freeze should never be used in a chiller.

How do I change the ratio of my glycol mixture?

If you have purchased a ratio that is higher than what your system needs, do not panic. You can still use this blend. However, you will need to perform onsite mixing. This process will involve adding water to the blend. Only use filtered, distilled or reverse-osmosis water. General tap water often has minerals such as calcium that can affect the chiller. After mixing and filling the system, any air pockets will need to be removed to prevent system frothing in the chiller.

What type of piping should I use for my glycol mixture?

Copper or ABS piping remain industrial standards for system piping. PVC is also sometimes used. The most important thing to consider when setting up a new system, is that the piping is properly sized. An undersized pipe may accidentally increase the pressure and could risk the rest of the system. Whereas, an oversized pipe may lower overall efficiency. Glycol is not recommended with galvanized piping, as it may adversely react with Zinc.

Will adding glycol change anything in my chiller setup?

Since many chillers are factory set for water only solutions, some minor adjustments may need to be made. Areas such as the evaporator, pump, and hot gas bypass valve may need adjustments. Glycol has a lower specific heat capacity and a lower heat transfer efficiency. These factors must be considering when designing for a particular system. A trained professional should be able to easily make the necessary changes. The addition of glycol also changes maintenance concerns, as the new element will need to be tested and maintained along with the mechanical elements of the machine.

Should I use glycol in my system?

If your system or atmosphere have the potential to go below 32°F (0°C), then a glycol-water mixture should be used. A chiller’s process fluid should never freeze, as this stops the chiller’s ability to do work, and could even cause mechanical damage. To prevent these problems, talk to an expert and discover the best glycol mixture for your system.

Still have questions? Comment below and one of our experts will answer it as soon as they can. Or even better! Call a Chase Cooling Expert.

What are the different types of compressors in industrial chillers?

If you are currently in the industrial chiller market, you have probably noticed that different chiller units have different compressor types. You may be wondering what the details of these different compressors are. Having a basic understanding of the core mechanisms of your unit not only provides you with a better appreciation for the unit, but also helps in your general maintenance and troubleshooting efforts.

Compressors are vitally important to the overall chiller system. They take

in low-pressure refrigerant vapor from the evaporator and compress it. The

resulting hot, high-pressure gas is discharged to the condenser. Once cooled in the condenser, the refrigerant

continues through the expansion device and enters the evaporator. There, it

chills the process fluid. Without a

working compressor, the refrigerant cycle simply cannot function.

Chase Chillers feature four different types of positive displacement

compressors: reciprocating, rotary vane, scroll, and screw. The compressor type

largely aligns with the size and capacity of the chiller itself. Continue

reading below for more information on the basics of the different compressor

types.

Reciprocating

Compressors

Reciprocating compressors use a piston and cylinder to compress incoming refrigerant. As the piston moves downward, refrigerant is drawn into the cylinder. The piston then moves upwards compressing the refrigerant and discharging it downstream to the condenser. Intake and exhaust valves ensure that the refrigerant does not flow backwards. These types of compressors are very economical and efficient in smaller applications. As with rotary vane and scroll compressors discussed below, reciprocating compressors consist of a hermetically sealed design. Chillers set up for small to medium heat loads, such as QBS and some QBE models match well with this type of compressor.

Rotary

Vane

Rotary vane compressors typically are quieter than other options. They consist of vanes or blades that are attached to a core rotor. The rotor is positioned off-center within its cylinder, creating multiple areas of varying sizes. The refrigerant enters the cylinder at the largest of these areas. As the rotor turns, the fluid is forced into smaller areas and compresses. Once compressed, the fluid exits the cylinder and continues through the rest of the system. Typically, industrial chillers with this compressor type only contain one compressor per unit. This compressor type is available in certain QBE models and the smallest CWT model.

Scroll

The most common compressor type in industrial chillers is the scroll. It is a powerhouse of a design and is able to handle significantly larger loads than the other compressor types. Found in our larger units, CWB, CWE & CWT, scroll compressors work by compressing the refrigerant between two spiral plates, one stationary and one orbiting. As the spirals move in an offsetting pattern, the trapped air is forced into smaller spaces as it moves towards the center. The compressed fluid exits through the center outlet and into the rest of the system. Multiple scroll compressors can be used in a single cooling unit, a feature great for building in redundancy and providing highly efficiency partial loads. With fewer moving parts, they are often more reliable and efficient than reciprocating options.

Screw

Rotary screw compressors have two interlocking helical rotors mounted inside a casing. As the rotors turn, the gas is forced from the suction end of the casing to the discharge end. The available space between the rotors and the casing becomes increasingly smaller as the gas moves along the length of the screw, increasing the pressure. Screw compressors are useful for varying the cooling output and are found in the largest chiller units. This design is able to limit how much refrigerant is delivered and lends itself well to meeting the variable needs of some cooling processes. Chillers in the CWV series have this compressor type.

The chart below outlines which compressor type is present in which Chase Chillers model:

| Reciprocating | Rotary Vane | Scroll | Screw | |

| QBS | ✔ | |||

| QBE | ✔ | ✔ | ✔ | |

| CWT | ✔ | ✔ | ||

| CWE | ✔ | |||

| CWB | ✔ | |||

| CWV | ✔ |

Regardless of which unit you choose, you can trust that it will be backed by the Chase Cooling Systems quality assurance. Each compressor type has its perks and benefits certain systems over others. To make sure you have the best unit for your system, work with one of our cooling experts. They are available for consultation regardless of where you stand in the buying process. We want you to find the best fit for your needs. Our years of experience and knowledge make us a strong resource for this process.

Caring for Industrial Chillers

Chiller Preventative Maintenance

You value your chiller. It’s important for your system to

work properly. You want it to operate well. To run smoothly. To last a long

time.

You don’t want problems, delays, or shutdowns. So how can you prevent these from happening? By taking good care of your chiller, of course! Just like any machine, industrial chillers require regular, dutiful maintenance. Here is a checklist of 6 simple tasks you can do to keep your chiller in top shape.

- Pay attention to alarm signals. Every chiller design is different. However, almost every brand will contain automatic alarms. If something major is wrong, then most chillers are smart enough to recognize it. The built-in alarm system should let you know that there is a problem. In order to fix the problem, of course, you’ll need to know what the alarm codes mean. Consult your user manual for answers.

- Check & clean water strainer. The overall cleanliness of your system will determine how often this task needs to be performed. Depending on ambient conditions, complete this task on a weekly to monthly bias. To keep smooth operations, you must prevent grime and filth from entering into the system.

- Clean the condenser coils. Condenser filters and coil surfaces will accumulate dirt, which could impact overall chiller performance. Contaminants & debris complicate the heat transfer process and increase the effort required to perform the same amount of work. These substances prevent proper temperature from being achieved and lower what your chiller can do. At the very minimum, cleaning of these elements should occur monthly.

- Confirm the pressure of inlet, outlet, and, if applicable, tank. If the working conditions have changed for your chiller, then your chiller will not perform at its best. Regularly checking these metrics allows users to catch issues before they become too expensive. Changes here often signify a larger problem, especially if not corrected. If the pressure continues to be incorrect, you may need to call for engineering assistance.

- Maintain proper water level and flow. Low water level in the tank can cause the pump to cavitate, leading to damage or failure of the impeller. Non-pressurized tanks should have a sight tube to indicate the minimum and maximum water level. Pressurized tanks, which must be completely full, usually have an automatic or manual vent valve to expel any air. Check this metric regularly to prevent problems such as the evaporator freezing from low water flow.

- Schedule annual maintenance. Since chillers are closed circuit, many users believe there’s no need for service. This belief is wrong. Chillers require the same attention as other mechanical equipment do. To keep in the best condition, you’ll really want to regularly have an expert perform extensive maintenance. Trained technicians are able to test components, such as the electrical and refrigeration, that the typical user cannot.

Completing these basic maintenance tasks on a regular basis should not only increase your chiller performance, but also settle your worrying mind. By taking an active role in your chiller's life, you can take comfort in its increased reliability. With good care comes good quality.