A. The minimum installation clearance varies by series and model as shown in the table below. In addition, air flow from the condenser fan(s) must not be restricted in any way and care must be taken to avoid recirculation of air from the condenser fan(s). Refer to the unit’s user manual for further installation requirements.

| Series & Model | Front * | Back * | Left * | Right * |

| ACW | 31” (800 mm) | 31” (800 mm) | 31” (800 mm) | 31” (800 mm) |

| QBS | 31” (800 mm) | 31” (800 mm) | 31” (800 mm) | 31” (800 mm) |

| QBE 002~007 | 31” (800 mm) | 31” (800 mm) | 31” (800 mm) | 31” (800 mm) |

| QBE 008~025 | 31” (800 mm) | 31” (800 mm) | 4” (100 mm) | 31” (800 mm) |

| CWT 007~015 | 39” (1000 mm) | 39” (1000 mm) | 31” (800 mm) | 59” (1500 mm) |

| CWT 018~150 | 39” (1000 mm) | 39” (1000 mm) | 59” (1500 mm) | 59” (1500 mm) |

| CWE | 39” (1000 mm) | 31” (800 mm) | 0” (0 mm) | 59” (1500 mm) |

| CWE | 39” (1000 mm) | 31” (800 mm) | 59” (1500 mm) | 0” (0 mm) |

| HWE | 39” (1000 mm) | 31” (800 mm) | 59” (1500 mm) | 59” (1500 mm) |

| CWB | 59” (1500 mm) | 59” (1500 mm) | 59” (1500 mm) | 59” (1500 mm) |

| CWM | 31” (800 mm) | 31” (800 mm) | 31” (800 mm) | 31” (800 mm) |

* Front refers to the end of the chiller where the controller is located. Back, Left, and Right are relative to standing and facing the Front of the chiller.

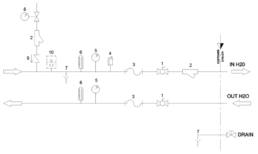

A. The diagrams below show the components recommended for our QBE chillers, depending on whether the tank is non-pressurized (i.e., “open” or “atmospheric” tank) or pressurized (“closed” tank). Refer to the appropriate unit’s user manual as some of these components may be factory installed or shipped loose for field installation. The user manual also provides additional model-specific details and recommendations.

Recommended water circuit for chiller with integral non-pressurized water storage tank:

Recommended water circuit for chiller with integral pressurized water storage tank:

| Legend: | 1 – Ball valve, full-port | 6 – Temperature gauge |

| 2 – Strainer, 20 mesh or finer | 7 – Drain | |

| 3 – Vibration dampener | 8 – Automatic fill valve | |

| 4 – Vent valve | 9 – Check valve | |

| 5 – Pressure gauge | 10 – Expansion vessel |

A. Refer to the table below, showing the heat rejection for each model at nominal rating conditions of 95°F ambient, 55°F fluid inlet, and 45°F fluid outlet with 0% glycol concentration.

| Model * | Heat Rejection (Btu/h) |

| QBE 002-E | 9,810 |

| QBE 003-E | 10,182 |

| QBE 004-E | 13,985 |

| QBE 005-E | 16,040 |

| QBE 006-E | 20,174 |

| QBE 007-E | 27,735 |

| QBE 009-E | 28,137 |

| QBE 012-E | 36,163 |

| QBE 005-R | 20,263 |

| QBE 006-R | 24,477 |

| QBE 007-R | 29,442 |

| QBE 009-R | 29,381 |

| QBE 012-R | 40,222 |

| QBE 014-R | 49,250 |

| QBE 020-R | 58,816 |

| QBE 025-R | 75,428 |

| CWT 010-R | 27,372 |

| CWT 015-R | 45,313 |

| CWT 018-R | 57,142 |

| CWT 020-R | 71,156 |

| CWT 030-R | 88,415 |

| CWT 038-R | 116,094 |

| CWT 040-R | 144,652 |

| CWT 045-R | 136,317 |

| CWT 055-R | 171,215 |

| CWT 065-R | 211,111 |

| CWT 075-R | 226,669 |

| CWT 090-R | 284,551 |

| CWT 110-R | 338,276 |

| CWT 130-R | 429,469 |

| Model * | Heat Rejection (Btu/h) |

| CWE/HWE 013-R | 47,122 |

| CWE/HWE 021-R | 72,815 |

| CWE/HWE 026-R | 84,047 |

| CWE/HWE 036-R | 112,316 |

| CWE/HWE 041-R | 143,944 |

| CWE/HWE 046-R | 158,288 |

| CWE/HWE 053-R | 183,012 |

| CWE/HWE 068-R | 215,980 |

| CWE/HWE 075-R | 221,641 |

| CWE/HWE 085-R | 281,501 |

| CWE/HWE 100-R | 323,540 |

| CWE/HWE 110-R | 363,143 |

| CWE/HWE 125-R | 406,109 |

| CWE/HWE 140-R | 459,584 |

| CWB 140-R | 442,375 |

| CWB 160-R | 546,599 |

| CWB 190-R | 591,547 |

| CWB 220-R | 712,786 |

| CWB 270-R | 852,579 |

| CWB 300-R | 960,112 |

| CWB 320-R | 1,018,275 |

| CWB 380-R | 1,180,863 |

| CWB 420-R | 1,318,320 |

| CWB 450-R | 1,451,640 |

| CWB 510-R | 1,609,285 |

| CWB 570-R | 1,852,009 |

* Model suffix indicates voltage: E = 230/1/60 R = 460/3/60

A. Minimum wire size and maximum fuse size are shown below for each model. Refer to the appropriate wiring diagram for further electrical details.

| Model * | Maximum Fuse Size (A) | Minimum Wire Size |

| ACW001-P | 6 | 16 AWG |

| ACW002-P | 6 | |

| QBS001-P | 13 | 14 AWG |

| QBS002-P | 13 | |

| QBS001-E | 10 | 16 AWG |

| QBS002-E | 10 |

| Model * | Maximum Fuse Size (A) | Minimum Wire Size |

| QBE 002-E | 10 | 16 AWG |

| QBE 003-E | 16 | 14 AWG |

| QBE 004-E | 16 | |

| QBE 005-E | 16 | |

| QBE 006-E | 20 | 12 AWG |

| QBE 007-E | 25 | |

| QBE 009-E | 25 | |

| QBE 012-E | 32 | |

| QBE 005-R | 10 | 14 AWG |

| QBE 006-R | 10 | |

| QBE 007-R | 12 | |

| QBE 009-R | 10 | |

| QBE 012-R | 12 | |

| QBE 014-R | 16 | 12 AWG |

| QBE 020-R | 16 | |

| QBE 025-R | 20 |

| Model* | Maximum Fuse Size (A) | Minimum Wire Size |

| CWT 010-R | 10 | 12 AWG |

| CWT 015-R | 12 | |

| CWT 018-R | 16 | |

| CWT 020-R | 20 | |

| CWT 030-R | 25 | 8 AWG |

| CWT 038-R | 32 | |

| CWT 040-R | 32 | |

| CWT 045-R | 35 | 6 AWG |

| CWT 055-R | 40 | |

| CWT 065-R | 50 | |

| CWT 075-R | 60 | 4 AWG |

| CWT 090-R | 63 | |

| CWT 110-R | 75 | |

| CWT 130-R

CWT 150-R |

75

100 |

2 AWG |

| Model * | Maximum Fuse Size (A) | Minimum Wire Size |

| CWE/HWE 013-R | 15 | 12 AWG |

| CWE/HWE 021-R | 20 | |

| CWE/HWE 026-R | 20 | |

| CWE/HWE 036-R | 30 | 10 AWG |

| CWE/HWE 041-R | 30 | |

| CWE/HWE 046-R | 40 | 8 AWG |

| CWE/HWE 053-R | 40 | |

| CWE/HWE 068-R | 50 | 6 AWG |

| CWE/HWE 075-R | 50 | 4 AWG |

| CWE/HWE 085-R | 60 | |

| CWE/HWE 100-R | 60 | |

| CWE/HWE 110-R | 70 | 2 AWG |

| CWE/HWE 125-R | 70 | |

| CWE/HWE 140-R | 80 |

| Model* | Maximum Fuse Size (A) | Minimum Wire Size |

| CWB 140-R | 100 | 2 AWG |

| CWB 160-R | 100 | 2 AWG |

| CWB 190-R | 100 | 2 AWG |

| CWB 220-R | 160 | 2/0 AWG |

| CWB 270-R | 160 | 2/0 AWG |

| CWB 300-R | 160 | 2/0 AWG |

| CWB 320-R | 200 | 4/0 AWG |

| CWB 380-R | 200 | 4/0 AWG |

| CWB 420-R | 250 | 250 kcmil |

| CWB 450-R | 250 | 250 kcmil |

| CWB 510-R | 315 | 400 kcmil |

| CWB 570-R | 315 | 400 kcmil |

* Model suffix indicates voltage: P=115/1/60, E = 230/1/60 R = 460/3/60

A. Glycol must be used in applications where the chiller is installed outdoors or when fluid temperatures below freezing are required. The freezing point of the water-glycol solution depends on the type and concentration of glycol, and whether or not the glycol contains inhibitors for corrosion protection. The table below provides a rough guide of the ethylene glycol concentration required for various ambient or operating temperatures. Check with your glycol supplier to ensure your system has adequate freeze protection. Choose a glycol concentration that results in a freezing point of several degrees below the lowest anticipated ambient or operating temperature.

| Temperature (°C) | 0 | -5 | -10 | -12 | -15 |

| Temperature (°F) | 32 | 23 | 14 | 10.4 | 5 |

| Ethylene glycol (% by volume) | 10 | 15 | 20 | 25 | 30 |

A. Install a buck-boost transformer to “boost” the 208/1/60 power supply to the 230/1/60 that the chiller requires. Contact Chase Cooling Systems or a certified electrician for proper transformer selection.