Specifically Catered to the Laser Industry

Laser Series chillers from Chase Cooling Systems are specially designed for the laser industry. Whether providing cooling for a laser welding, cutting, or marking machine, temperature control is important. You need a reliable, trustworthy machine to keep operations running and your equipment cool. We understand how important steady operations are, so we have taken what matters most and prioritized those elements into each unit in this series. With six separate models, there’s sure to be a unit that matches your needs.

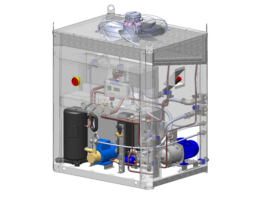

CHILLERS FOR BOTH

- Why not cool both the source and the optics at the same time? One unit, two independent cooling circuits! That’s the power of the Laser Series!

- Two pumps to provide independent water temperatures

- Separately set and control each circuit

- Electric heater keeps minimum water temperature to prevent cold start-up

- Save space with one machine

- Size range from 0.5 ton to 30 tons (2 – 100 kW)

- Wheel kits included on all models

Available Models

- QBE012-R TTM LSR

- QBE023-R TTM LSR

- QBE033-R TTM LSR

- QBE050-R TTM LSR

- CWE068-R TTM LSR

- CWE085-R TTM LSR (Coming Soon)

- CWE120-R TTM LSR (Coming Soon)

ELECTRICAL PANEL

→ Manufactured in compliance with international standards (EN 60204-1) using UL recognized components

→ Disconnect switch with door lock prevents access to panel when energized

→ Electronic phase monitor protects against reverse rotation or loss of phase

→ Circuit breakers for compressor, fans, pumps, and tank heater

→ Contacts for remote ON/OFF operation and remote alarm indication

→ Electrical cabinet constructed of powder-coated galvanized steel

MICROPROCESSOR CONTROLLER

→ Optimizes unit performance to maintain fluid temperatures in each circuit by controlling the electronic hot gas bypass valve (laser source circuit) and 3-way mixing valve (optics circuit)

→ Manages operation of the compressor and pumps, and controls the condenser fan speed

→ Operates the tank heater to maintain a minimum fluid temperature

→ Protected by a watertight, UV-blocking cover for extended LCD life

→ Includes an RS485 communication port and Ethernet with integrated web server

→ Displays fluid temperatures, key operating parameters, and the following alarm conditions

→ High and low refrigerant pressure

→ High compressor discharge temperature

→ Low fluid flow (evaporator differential pressure) and low fluid level (tank)

→ Flow switch in the optics circuit

→ Incorrect phase sequence

→ Compressor, pump, or fan motor protector tripped

→ Temperature probe failure

→ High fluid temperature

→ Evaporator anti-freeze

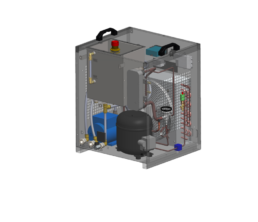

COOLING FOR OPTICS

Great for sensitive applications relying on deionized (DI) water. These units are designed to cool the optics of a laser machine.

-

- Stainless steel brazed plate heat exchanger

- Completely free from copper, aluminum, and carbon steel

- Comes fully packaged with a 4-gal tank and fixed-speed pump

- 0.5 ton (2 kW) cooling capacity

- VFD Pump

- Indoor Installation only

Available Models

-

- QBS002-E LSR

Note: QBE002 utilizes an electronic thermostat in place of the microprocessor controller

FACTORY TESTING OF EVERY UNIT

- Pressurization and helium leak detection of refrigeration circuit

- Pressurization and leak testing of fluid circuit

- Chiller performance and power consumption at full load

- Proper operation of all controls, safety devices, and alarms

- Electrical tests according to international standards (EN 60204)