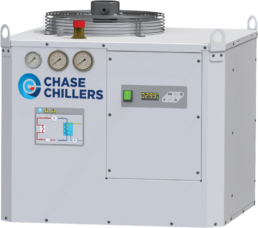

QBE Series fluid chillers provide 0.6 to 7 tons of cooling capacity in a range of air-cooled models. This powerful chiller’s compact layout is designed for easy maintenance and is suitable for outdoor installation (standard on 460/3/60 models, optional on 230/1/60). An electronic controller optimizes unit performance and displays key operating parameters and alarm conditions. For applications requiring tight temperature control, an optional hot gas bypass valve can be added. The fluid circuit is non-ferrous throughout and most models can operate with glycol concentrations up to 50% for low fluid temperature applications. The cabinet frame and panels are powder-coated steel and the condenser is electro-coated for corrosion protection. Numerous options are available to create a custom chiller for your application.

FLUID CIRCUIT

- Standard insulated plastic tank (unpressurized)

- Optional pressurized tank

- Tank includes fill port, drain valve, level gauge, and level sensor

- Insulated, non-ferrous centrifugal pump and fluid circuit

- Fluid bypass protects pump from damage if chiller inlet and outlet

are closed - Fluid differential pressure switch (QBE009-025) protects against

low-flow condition - Fluid pressure gauge (pump discharge)

- Ability to use glycol mixtures up to 50%

REFRIGERATION CIRCUIT

- Manufactured with high-quality materials following rigorous brazing procedures and conforming to international standards (PED 97/23/EC)

- Environmentally friendly R407C refrigerant

- Refrigerant sight glass with moisture indicator (QBE009-025) and filter-dryer

- Externally equalized thermostatic expansion valve (except QBE002)

- High and low pressure switches

- High and low pressure gauges (QBE009-025)

- High and low pressure access fittings for maintenance and troubleshooting

- Optional Hot Gas Bypass Valve (QBE003-025) for highly accurate control of outlet fluid temperature

COMPRESSOR

- Hermetic compressors (scroll, rotary, or reciprocating) chosen for reliability and efficiency

- Mounted on rubber isolators for noise reduction

- Scroll compressors are especially quiet and can handle liquid return without damage

- Three-phase models are protected against reverse rotation by an electronic phase monitor

- Crankcase heater prevents liquid slugging on start-up (QBE003-025)

EVAPORATOR

- Copper coaxial evaporators (QBE002-007) are especially reliable when dealing with contaminated fluids

- Stainless steel, brazed plate evaporators (QBE009-025) are compact and highly efficient

- Evaporators are protected against freezing by the microprocessor controller

CONDENSER

- Microchannel design is compact and highly efficient

- All-aluminum construction eliminates the risk of galvanic corrosion

- Epoxy-coated for corrosion resistance, even in aggressive environments

- Cleanable, stainless steel air filter (standard on QBE009-025, optional on QBE002-007)

- Condenser fan motor includes internal, self-resetting thermal protector

ELECTRICAL PANEL

- Manufactured in compliance with international standards (EN 60204) using UL-recognized components

- Electrical cabinet constructed of powder-coated galvanized steel

- Disconnect switch with door lock prevents access to panel when energized (QBE009-025)

MICROPROCESSOR CONTROLLER (QBE003-025)

- Optimizes unit performance and maintains fluid temperature

- Controls and displays the fluid temperature

- Turns the compressor on and off while protecting against short cycling

- Turns the pump and condenser fan on and off

- Protected by a watertight cover

- Displays key operating parameters and the following alarm conditions

- High and low refrigerant pressure

- Low fluid differential pressure (QBE009-025)

- Low fluid level

- Incorrect phase sequence (QBE009-025)

- Compressor, pump, or fan motor protector tripped (QBE009-025)

- Temperature probe failure

- High fluid temperature

- Evaporator anti-freeze

Note: QBE002 utilizes an electronic thermostat in place of the microprocessor controller

UNIT CONSTRUCTION AND MAINTENANCE

- Cabinet frame and panels are powder-coated and suitable for outdoor installation

- Panels are easily removed, providing convenient access for maintenance and repair

- All fasteners are stainless or zinc-plated steel for corrosion resistance

- Protection to IP44 standard on three-phase models

- For ease of installation all models include lifting eyes; QBE009-025 also have lifting holes in the base

- Wheel kits are available for all models

- Designed for ease of operation and maintenance

FACTORY TESTING OF EVERY QBE UNIT

- Pressurization and helium leak detection of refrigeration circuit

- Pressurization and leak testing of fluid circuit

- Chiller performance and power consumption at full load

- Proper operation of all controls, safety devices, and alarms

- Electrical tests according to international standards (EN 60204)