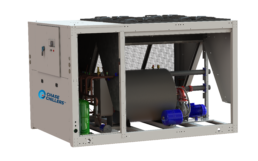

Comfort Cooling

CFT Series chillers, a variation of the CWB Series, have been optimized for operating conditions associated with comfort cooling applications. With capacities up to 85 tons, CFT Series chillers operate on 460/3/60 power and are made for outdoor installation. Among the standard features of this series are hermetic scroll compressors, microchannel aluminum condensers, axial fans, an electronic expansion valve, and a copper-brazed stainless steel evaporator. A microprocessor controller monitors the refrigerant and fluid circuits, and manages the entire system. Options include continuous fan speed control for operation in low ambient conditions, condenser e-coating for enhanced corrosion protection, and a variety of pump and tank configurations to suit your installation.

FLUID CIRCUIT

- Standard models include a stainless steel, brazed plate evaporator, without tank or pump

- Options include single and dual pumps in a variety of pressures

- Available with insulated tank in carbon steel

- Fluid differential pressure switch protects evaporator against low-

flow condition - Fluid pressure gauge (pump discharge pressure)

- Ability to use glycol mixtures up to 50%

- Suitable for Comfort Cooling Applications

REFRIGERATION CIRCUIT

- Manufactured with high-quality materials following rigorous brazing procedures and conforming to international standards (PED 2014/68/EU)

- Environmentally friendly R410A refrigerant

- Refrigerant sight glass with moisture indicator and filter-dryer

- Electronic expansion valve and liquid line solenoid valve

- High and low pressure transducers and switches

- High and low pressure gauges

- High and low pressure access fittings for maintenance and troubleshooting

COMPRESSOR

- Tandem, hermetic scroll compressors chosen for reliability

and efficiency - Multiple compressors for energy efficiency and low starting amps

- Mounted on rubber isolators for noise reduction

- Scroll compressors are especially quiet and can handle liquid return without damage

- Protected against reverse rotation by an electronic phase monitor

- Crankcase heater prevents liquid slugging on start-up

EVAPORATOR

- Stainless steel, brazed plate evaporators are compact and highly efficient

- Evaporators are protected against freezing by the microprocessor controller

- Evaporator has two refrigerant circuits and a single fluid circuit

(CFT230 to CFT300)

CONDENSER

- Microchannel design is compact and highly efficient

- All-aluminum construction eliminates the risk of galvanic corrosion

- Variable-speed fan allows operation over a wide ambient

temperature range (Option)

ELECTRICAL PANEL

- Manufactured in compliance with international standards (EN 60204) using UL-recognized components

- Electrical cabinet constructed of powder-coated galvanized steel

- Disconnect switch with door lock prevents access to panel when energized

MICROPROCESSOR CONTROLLER

- Optimizes unit performance and maintains fluid temperature

- Controls and displays the fluid temperature

- Turns the compressors on and off while protecting against short cycling

- Turns the pump(s) on and off; equalizes pump operating times

(double pump models) - Regulates condenser fan speed (option)

- Protected by a watertight cover

- Displays key operating parameters and the following alarm conditions

- High and low refrigerant pressure

- High refrigerant discharge temperature

- Low fluid differential pressure

- Incorrect phase sequence

- Compressor, pump, or fan motor protector tripped

- Temperature probe or pressure sensor failure

- High fluid temperature

- Evaporator anti-freeze

- Electronic expansion valve fault

UNIT CONSTRUCTION AND MAINTENANCE

- Cabinet frame and panels are powder-coated and suitable for outdoor installation

- Panels are easily removed, providing convenient access for maintenance and repair

- All fasteners are stainless or zinc-plated steel for corrosion resistance

- Protection to IP54 standard on all models; suitable for outdoor installation

- Designed for ease of operation and maintenance

FACTORY TESTING OF EVERY CFT UNIT

- Pressurization and helium leak detection of refrigeration circuit

- Pressurization and leak testing of fluid circuit

- Chiller performance and power consumption at full load

- Proper operation of all controls, safety devices, and alarms

- Electrical tests according to international standards (EN 60204)