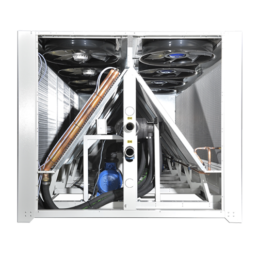

Integrated Free-cooling

CWB FC Series units consist of a standard refrigerated fluid chiller coupled with a free cooling option in a single, air-cooled package. As the ambient temperature falls below the desired fluid temperature, the free cooling circuit is engaged. Sometimes referred to as a “dry cooler”, free coolers use ambient temperatures to chill process fluids. Environments with ambient temperatures below the necessary cooled temperature can see a strong energy savings benefit to this type of machine. A microprocessor controller seamlessly adjusts the amount of free cooling (from 0% to 100%) depending on system settings. As the ambient temperature drops, then more of the process heat load can be absorbed in the free-cooler. When operating in 100% free-cooling mode, the only cost of cooling is for the fans, providing substantial energy savings. CWB FC Series models share many of the features and options of the CWB Series and are available in rated capacities to 70 tons.

FREE-COOLING MODES OF OPERATION

Summer Mode: Free-Cooling Off

-

- When the ambient temperature exceeds the temperature of the returning water, the free-cooling coils are bypassed and the CWB FC operates like a traditional chiller.

Intermediate Mode: Free-Cooling & Chiller

-

- When the ambient temperature is lower than the temperature of the returning water, water is precooled by the free-cooling coils; final cooling to the set point is achieved via the refrigeration circuit.

Winter Mode: 100% Free-Cooling

-

- When the ambient temperature is several degrees below the desired outlet water temperature, 100% of the heat load can be absorbed by the free-cooing coils and the refrigeration system remains off.

REFRIGERATION CIRCUIT

-

-

- Manufactured with high-quality materials following rigorous brazing procedures and conforming to international standards (PED 2014/68/EU)

- Environmentally friendly R410A refrigerant

- Refrigerant sight glass with moisture indicator and filter-dryer

- Electronic expansion valve and liquid line solenoid valve

- High and low pressure transducers and switches

- High and low pressure gauges

- High and low pressure access fittings for maintenance and troubleshooting

-

COMPRESSOR

-

-

- Tandem, hermetic scroll compressors chosen for reliability

and efficiency - Multiple compressors for energy efficiency and low starting amps

- Mounted on rubber isolators for noise reduction

- Scroll compressors are especially quiet and can handle liquid return without damage

- Protected against reverse rotation by an electronic phase monitor

- Crankcase heater prevents liquid slugging on start-up

- Tandem, hermetic scroll compressors chosen for reliability

-

EVAPORATOR

-

-

- Stainless steel, brazed plate evaporators are compact and highly efficient

- Evaporators are protected against freezing by the microprocessor controller

-

CONDENSER

-

-

- Microchannel design is compact and highly efficient

- All-aluminum construction eliminates the risk of galvanic corrosion

- Variable-speed fans allow operation over a wide ambient temperature range

-

FREE-COOLING CIRCUIT

FREE-COOLER

-

-

- Coil constructed of copper tubes and aluminum fins

- Axial fans with on/off operation supplied as standard

- EC fans with continuous speed control available as an option

-

FLUID CIRCUIT

- Standard models include a stainless steel, brazed plate evaporator, without tank or pump

- Options include single and dual pumps in a variety of pressures

- Available with insulated tank in carbon steel or stainless steel

- Optional non-ferrous fluid circuit

- Fluid differential pressure switch protects evaporator against low-

flow condition - Fluid pressure gauge (pump discharge pressure)

- Ability to use glycol mixtures up to 50%

- Three-way valve and actuator (positioner) for modulating water flow through the free-cooler

ELECTRICAL PANEL

- Manufactured in compliance with international standards (EN 60204) using UL-recognized components

- Electrical cabinet constructed of powder-coated galvanized steel

- Disconnect switch with door lock prevents access to panel when energized

MICROPROCESSOR CONTROLLER

- Optimizes unit performance and maintains fluid temperature

- Switches seamlessly between operating modes (summer, intermediate, and winter)

- Modulates water flow through the free-cooler based on ambient temperature

- Controls and displays the fluid temperature

- Turns the compressors on and off while protecting against short cycling

- Turns the pump on and off and regulates condenser fan speed

- Protected by a watertight cover

- Displays key operating parameters and the following alarm conditions

- High and low refrigerant pressure

- High refrigerant discharge temperature

- Low fluid differential pressure

- Incorrect phase sequence

- Compressor, pump, or fan motor protector tripped

- Temperature probe or pressure sensor failure

- High fluid temperature

- Evaporator anti-freeze

- Electronic expansion valve fault

- Optional remote control panel

UNIT CONSTRUCTION AND MAINTENANCE

- Cabinet frame and panels are powder-coated and suitable for outdoor installation

- Panels are easily removed, providing convenient access for maintenance and repair

- All fasteners are stainless or zinc-plated steel for corrosion resistance

- Protection to IP54 standard on all models; suitable for outdoor installation

- Designed for ease of operation and maintenance

FACTORY TESTING OF EVERY CWB FC UNIT

- Pressurization and helium leak detection of refrigeration circuit

- Pressurization and leak testing of fluid circuit

- Chiller performance and power consumption at full load

- Proper operation of all controls, safety devices, and alarms

- Electrical tests according to international standards (EN 60204)